Automatic gates offer convenience and security for your Los Angeles home, but they must meet specific safety standards to protect you, your family, and visitors. UL325 is the safety standard that covers automatic gate operators and establishes requirements for preventing injuries and accidents. Your automatic gate is UL325 compliant if it has the required number of entrapment protection devices for its type, proper monitoring systems that cannot be bypassed, and meets construction standards outlined in both UL325 and ASTM F2200.

Understanding whether your gate meets these requirements is important for your safety and liability protection. Many homeowners in Los Angeles have automatic gates but may not know if their systems follow current safety standards, especially if the gate was installed before August 2018 when the latest UL325 standards took effect. Older gates may need updates to meet current requirements.

This guide walks you through what UL325 compliance means, the specific requirements for different gate types, and a practical checklist you can use to evaluate your own automatic gate system. You will learn how to identify potential safety gaps and when to call a professional for help.

Understanding UL325 Compliance for Automatic Gates

UL 325 is a nationally recognized safety standard that governs how automatic gates operate, requiring specific protections to prevent injuries and deaths. This standard was created by Underwriters Laboratories and sets mandatory requirements for gate operators sold and installed across the United States, including Los Angeles.

What Is UL 325 and Who Sets the Standard?

UL 325 is a safety standard that regulates automatic gate operators and related equipment. The standard covers swing gates, sliding gates, and vertical lift gates used at your home.

The standard requires gate operators to have built-in safety features. Your gate must include at least two independent entrapment protection devices. These typically include photoelectric sensors that create an invisible beam across the gate path and contact sensors on the gate’s edge.

UL 325 also sets limits on how fast your gate can move and how much force it can apply. These restrictions reduce the risk of serious injury if someone or something gets caught in the gate’s path. The standard requires your gate operator to monitor safety devices continuously and stop working if a safety device fails or gets disconnected.

The Role of Underwriters Laboratories in Gate Safety

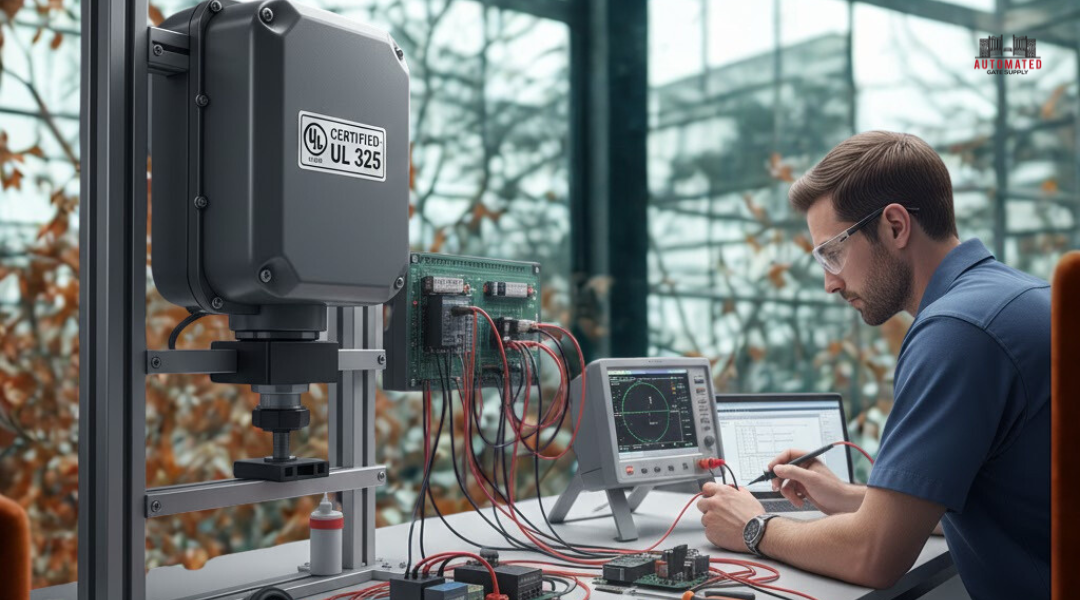

Underwriters Laboratories is an independent testing organization that has developed safety standards for electrical and mechanical products since 1894. UL tests gate operators and awards certification to products that meet their safety requirements.

When you see a UL 325 label on a gate operator, it means the product passed rigorous testing. UL evaluates gate operators for electrical safety, mechanical durability, and proper safety device integration. The organization updates the standard regularly based on accident data and new technology.

Manufacturers must submit their gate operators to UL for testing before they can use the UL 325 certification mark. Your gate installer should only use UL 325-listed operators to ensure your system meets current safety requirements.

Why UL325 Matters for Los Angeles Homeowners

Los Angeles building codes require automatic gates to comply with UL 325 safety standards. Your gate installation must pass inspection to meet local requirements.

Your insurance coverage may depend on UL 325 compliance. Many insurance companies require proper safety standards for automated gates. If your gate injures someone and doesn’t meet UL 325 requirements, your insurer could deny your claim.

You face legal liability if your non-compliant gate causes injury or death. California law holds property owners responsible for maintaining safe conditions. A gate that lacks proper safety devices creates a significant risk, especially if children are present in your neighborhood.

Your property value benefits from a properly compliant gate system. Buyers and inspectors look for safety compliance during real estate transactions.

Key UL325 Requirements for Automated Gate Systems

UL325 mandates specific safety features for automatic gates, including multiple entrapment protection devices, proper sensor placement, and clear warning labels. Your gate must meet these requirements based on its class and type, whether it’s a slide gate, swing gate, or vertical lift system.

Entrapment Protection Essentials

Your automated gate system needs at least two independent means of entrapment protection in each direction of travel. These protections prevent injuries when someone or something gets caught in the gate’s path.

The type of protection depends on your gate style. Horizontal slide gates require two devices for both opening and closing. Swing gates also need two devices in each direction, unless one direction has no entrapment zone. Vertical lift gates need one device when opening and two when closing.

UL325 recognizes five protection types. Type A is inherent system protection. Type B1 includes non-contact sensors like photoelectric beams. Type B2 covers contact sensors such as edge devices. Type C involves force-limiting mechanisms or pressure relief devices. Type D requires continuous pressure on the control to move the gate.

You cannot use the same type of device for both protection requirements. For example, you can’t rely on two photoelectric sensors alone. You need different protection types, such as one photoelectric sensor and one edge sensor.

Mandatory Safety Devices and Placement

Edge sensors must be installed on all closing edges that could trap people or vehicles. These sensors detect contact and immediately reverse the gate’s motion. Photoelectric sensors create an invisible beam across entrapment zones and must be placed no higher than 12 inches from the ground for vehicular gates.

Access controls need to be mounted at least 6 feet away from any moving gate parts. This distance prevents anyone from getting caught while operating the controls. Your transmitters and remotes should stay out of children’s reach.

All external entrapment protection devices must be monitored by the gate operator. This monitoring ensures the safety devices are working properly. You cannot use resistors or other components to bypass these monitoring functions. The 2018 UL325 update strictly prohibits any tampering with monitoring features.

Warning signs must be clearly visible on both sides of your gate. These signs alert pedestrians and drivers to stay clear of the moving gate. Your installation should include separate pedestrian walkways with proper signage directing people away from the vehicle gate.

Labeling, Documentation, and Testing for Compliance

Your gate operator must display a UL325 label showing compliance with the current standard. Gates manufactured after August 1, 2018 must meet the 7th Edition requirements. This label confirms the operator was tested at a nationally recognized laboratory.

You need to maintain all installation documentation, including the manufacturer’s manual and installer’s certification. These documents prove your system was installed according to UL325 standards. Your installer should provide written confirmation of which entrapment protection devices were installed and where.

Regular testing ensures your safety devices continue working properly. Test photoelectric sensors monthly by breaking the beam while the gate closes. The gate should stop and reverse immediately. Test edge sensors by applying light pressure to the edge during gate movement.

Your system should be inspected annually by a qualified technician. This inspection includes checking all monitoring functions, verifying sensor alignment, and testing emergency stop features. Documentation of these inspections helps demonstrate ongoing compliance.

Gate Operator Types and Classes Defined

UL 325 divides gate operators into four distinct classes based on location type and access level. The class assigned to your gate determines which safety requirements apply and how many entrapment protection devices you need.

Residential Vehicular Gate Operator Overview

A Class I residential vehicular gate operator serves garages or parking areas for homes with one to four single-family units. This classification applies to most homes in Los Angeles with automatic gates. Your residential gate system must meet specific safety standards even though it serves fewer people than commercial systems.

Class I operators require at least two independent entrapment protection devices for each direction of gate travel. The devices must be different types, such as a photoelectric sensor paired with a contact edge sensor. You cannot use the same type of device twice to meet this requirement.

Your gate operator must also monitor all external entrapment protection devices. If a sensor fails or gets disconnected, the system should detect the problem and prevent the gate from operating.

Other Gate Operator Classes and Their Differences

Class II covers commercial and general access vehicular gates at locations like apartment buildings with five or more units, hotels, and retail stores. These systems serve the general public and face higher traffic volumes than residential gates.

Class III applies to industrial or limited access locations such as factories and loading docks. These gates do not service the general public but handle frequent use by authorized personnel.

Class IV designates restricted access gates in highly secure areas like airport security zones. Security personnel supervise these locations and control who can access them.

Each class requires two means of entrapment protection in each direction of travel where entrapment risk exists. The specific devices needed depend on whether you have a slide gate, swing gate, vertical lift gate, or vertical pivot gate.

How Operator Class Impacts Compliance

Your gate’s classification determines which entrapment protection devices you must install and how you configure them. A Class I residential system needs fewer safety features than a Class II commercial gate serving a large apartment complex.

The operator class also affects installation requirements under ASTM F2200 standards. Residential gates need proper signage and pedestrian pathways, but commercial gates face stricter requirements for pedestrian separation and warning signs.

Misclassifying your gate operator can create serious liability issues. If you install a Class I system in a location that requires Class II standards, your gate does not meet code requirements. Work with a qualified installer who can correctly classify your gate based on its location and intended use.

Design and Construction Standards for Compliance

UL 325 compliance starts with proper gate design and construction that meets specific safety standards. The type of gate you have determines where entrapment zones exist and what safety devices you need to install.

Gate Construction and ASTM F2200 Standards

ASTM F2200 works alongside UL 325 to set requirements for gate construction materials and structural integrity. Your gate must be built with materials strong enough to withstand repeated use without failing or creating safety hazards.

The standard requires specific spacing between gate components to prevent entrapment. Vertical pickets or bars must be spaced close enough that a 4-inch sphere cannot pass through. This prevents children from getting their heads stuck between openings.

Your gate’s weight and force capacity must match your operator’s capabilities. Gates that are too heavy or improperly balanced create excessive force that can cause serious injuries. The frame must be rigid enough to prevent sagging or twisting during operation.

Gate Types: Slide, Swing, Vertical Lift, and Pivot

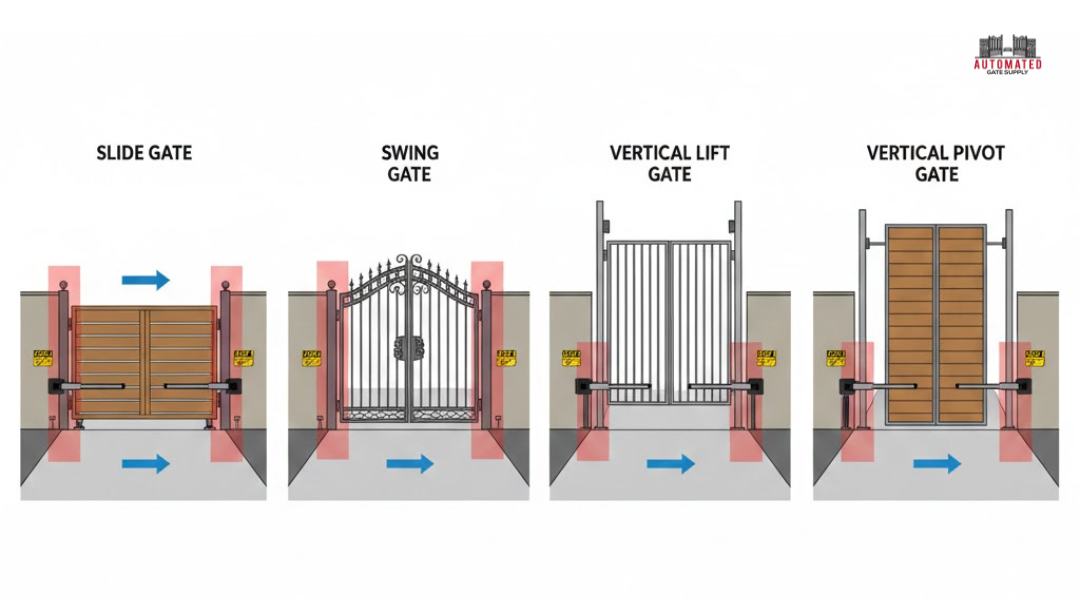

Horizontal slide gates move parallel to the fence line and are common in Los Angeles driveways with limited space. These gates create entrapment risks along the leading edge and between the gate and posts.

Horizontal swing gates open inward or outward like doors. Single or double swing gates are popular for residential properties. They create pinch points at hinges and along the opening arc.

Vertical lift gates raise straight up and are less common in homes. These gates create overhead entrapment zones and crushing risks underneath.

Vertical pivot gates rotate on a central pivot point. They combine risks from both swing and lift gate types, with pinch points at the pivot and along edges.

Identifying Entrapment Zones by Gate Type

Each gate type has specific areas where people or objects can get trapped or struck. Your safety devices must protect all these zones to meet UL 325 standards.

Horizontal slide gates have entrapment zones at the leading edge, trailing edge, and posts. You need protection where the gate meets the catch post and along the entire closing edge.

Horizontal swing gates create pinch points at hinges, along edges, and in the swing arc path. The area between the gate and fence post requires monitored protection on both sides.

Vertical lift and pivot gates need protection above, below, and around all moving edges. Overhead entrapment zones require specific safety sensors that detect people or objects in the gate’s path.

Homeowner Checklist for UL325 Compliance in Los Angeles

Los Angeles homeowners with automated gate systems need to verify their gates meet UL325 safety requirements through proper equipment, regular maintenance, and adherence to local building codes.

Verification of Installed Safety Components

Your automated gate system requires at least two independent safety devices at each entrapment point to meet UL325 standards. Check for photoelectric sensors that create an invisible beam across the gate’s path. These sensors should stop or reverse the gate when something blocks the beam.

Look for contact sensors on the gate’s leading edge. These safety edges detect physical contact and immediately stop the gate’s movement.

Your gate operator must monitor these safety devices continuously. If a sensor fails or becomes disconnected, the system should stop working or alert you to the problem. Test this by carefully blocking the photoelectric beam while the gate operates. The gate should stop or reverse.

Verify that your control devices sit at least 6 feet from the gate’s moving parts. Remotes, keypads, and push buttons should let you see the entire gate area when you operate it. Your system needs a clearly marked emergency stop button that you can easily reach.

Check that your gate’s opening and closing speeds fall within safe limits. The gate should move slowly enough that you could react if someone walked into its path.

Routine Gate Inspections and Maintenance

Test your gate’s safety features monthly to catch problems early. Activate the photoelectric sensors by waving your hand through the beam while the gate moves. Place a small object like a cardboard box in the gate’s path to test the contact sensors.

Listen for unusual sounds during operation. Grinding, scraping, or loud noises often signal mechanical problems that need attention.

Inspect the gate’s hinges, rollers, and tracks for wear every three months. Clean debris from tracks and remove any obstructions near the gate’s path.

Schedule professional maintenance at least once per year. Trained technicians can identify issues you might miss and adjust force settings to maintain UL325 compliance. They can also verify that your safety monitoring systems work correctly.

Keep records of all maintenance and repairs. Document when you test safety features and note any problems you find. These records prove your diligence if questions arise about your gate’s safety.

Local Regulations and Code Compliance

Los Angeles County requires automated gate systems to meet UL325 standards as part of building codes. If your gate was installed before January 2016, it may need upgrades to meet current requirements.

Contact the Los Angeles Department of Building and Safety before making changes to your gate system. Some modifications require permits, especially if you alter electrical components or replace the gate operator.

Professional installation ensures your automated gate system meets both UL325 standards and local codes from the start. Licensed contractors know Los Angeles-specific requirements and can document compliance for your records.

Your homeowner’s insurance may require UL325 compliance. Check your policy and notify your insurer about your gate system. Non-compliant gates could affect your coverage if an accident occurs.

If you bought a home with an existing gate, request documentation from the previous owner showing the system meets current standards. Without proof of compliance, schedule an inspection with a qualified gate professional to assess your system and recommend any needed upgrades.

Professional Installation and Ongoing Safety

Getting your automatic gate installed by qualified professionals and keeping it maintained properly are both essential for meeting UL325 standards. These two steps work together to keep your gate safe and compliant for years to come.

Why Professional Installation Matters

A qualified professional installer knows how to set up your gate system correctly from the start. They understand where to place safety sensors so they actually detect people and objects in the gate’s path. They also know the proper positioning for photoelectric sensors and pressure-sensitive edges that prevent entrapment.

DIY installations often miss critical safety requirements. Your installer might place sensors at the wrong height or distance, which means they won’t work when needed. Professional installers also handle the electrical wiring safely and install emergency release mechanisms in accessible locations.

Licensed professionals stay current with Los Angeles building codes and UL325 requirements. They test each safety feature before finishing the job. This testing includes checking that your gate stops or reverses when it hits an obstruction and that all sensors communicate properly with the operator.

Maintaining UL325 Compliance Over Time

Your gate needs regular inspections to stay compliant and safe. You should check safety sensors monthly by testing if your gate stops when you place an object in its path. Look for any physical damage to sensors, wiring, and the gate structure itself.

Schedule professional maintenance every six months. A technician will calibrate your sensors, lubricate moving parts, and replace worn components before they fail. They’ll also verify that your emergency release still works and that all safety labels remain visible and readable.

Keep records of all inspections and repairs. These documents prove you’ve maintained your system properly if an incident occurs. Replace any damaged safety equipment immediately rather than waiting for your next scheduled service. Safety sensors lose effectiveness over time due to weather exposure and normal wear.